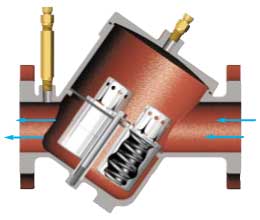

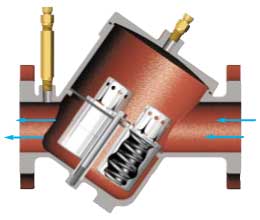

| Like all Griswold flow control valves, the Uni-Flange features easily accessible flow cartridges, which means mainte- nance or inspection of the valve can be completed without having to break any piping connections. The valve hous- es up to three 2lr stainless steel flow cartridges, allowing for a total maximum flow rate of 171 gpm at 2-32 PSID, encompassing nominal ASHRAE recommended flow rates. |

|

| VERSATILITY |

|

• Precision 100% Stainless Steel Flow Control Cartridge ±5% Accuracy

• Ductile Iron Body for HVAC Strength & Pressure/Temp Rating

• Y-Pattern Housing Design Allows Inspection or Removal of Cartridge Without Breaking Piping Connections

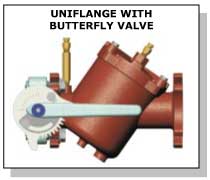

• Lug Pattern Flanged Butterfly Valve or Flanged Ball Valve Available for Isolation

• Flanged Ends for Mounting to 2lu, 2-1/2ln, 3l1 ANSI 150 lb. Flanged Piping System *1

• Supplied with Two Pressure/Temperature Test Valves

• Line Transition Possible Through Uni-Flange Body

|

|

|

| AIR HANDLING PRODUCT GUIDE |

| LINE SIZE |

ASHRAE FLOW

RECOMMENDATION (GPM)

@ 4 FT/100 FT HEAD LOSS |

VELOCITY

(FEET PER

SECOND) |

TONS *2

COOLING @

(2.5 GPM/TON) |

MBH *2

HEATING @

(20 MBH/GPM) |

| 1-1/2" |

27 |

4.0 |

10 |

540 |

| 2" |

40 |

3.8 |

16 |

800 |

| IR-IS/IB-IY FLOW |

@ 57 |

5.5(2"LINE) |

23 |

1114 |

| 2" |

40 |

3.8 |

16 |

800 |

| 2-1/2" |

75 |

5.0 |

30 |

1500 |

| UNI-FLANGE FLOW |

@ 171 |

7.5(3"LINE) |

90 |

3400 |

|

|

*1 2lN size will use a 2-1/2lA reducing flange as shown in drawing next page.

*2 Approximate values based on typical air and water design temperatures and 4 row coils

|

|

|