| Function |

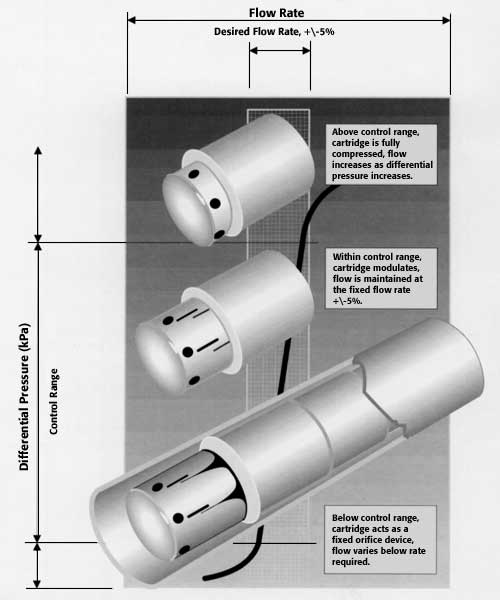

The FlowCon High Flow series valves utilize precision calibrated, stainless steel, flow rate cartridges to achieve the desired flow rate. Each cartridges is manufactured to deliver a specific flow rate over a wide operating range of differential pressures at a tolerance of +/- 5%. They do this by automatically adjusting the open orifice area of the cartridge in reaction to pressure differential changes.

The High Flow Series valves requiring more flow than can be achieved by a single cartridge, (9.46 l/s), utilize multiple cartridges mounted in parallel into webbing within the valve body.

The sum of the flow rates of the cartridges within any one valve is the flow rate for that valve. (Example: A (6") DN 150 valve containing 4 cartridges, 2 at 6 l/s and 2 at 5 l/s will have a total flow rate of 22 l/s. )

As shown in the graph, the cartridge is simply a fixed orifice device below its' pressure differential range, (this allows a modulating valve in the same circuit to operate with valve authority up to the flow rate specified.)

Once in the pressure differential range, the spring mounted cup of the cartridge actually slides within the cartridge housing adjusting the effective open orifice area of the cartridge to the exact point where the specified flow rate will be delivered. (As the pressure differential across the valve increases, the orifice area close, .. as it decreases, the orifice are opens.) All cartridges, in the High Flow valves that contain multiple cartridges, will operate simultaneously.

|

|

|

|

|

|

|